Indian Scientists have indigenously developed toxic-free and superior multilayer technology that packages together electronic components like resistors, capacitors to produce multilayer circuits. These technologies, known as Low-Temperature Cofired Ceramic (LTCC) and High-Temperature Cofired Ceramic HTCC substrates with applications as satellite communication components, are currently being imported in India. The indigenous development can plug the money drain through import substitution and support the country’s strategic sectors. Low orbit satellites satellite systems which are in demand today need a sustainable technology supporting reduced satellite volume and mass, besides reduced production time and affordable cost. Hybrid microsystems based on LTCC technology (integration of passive components, such as a capacitor, resistor, inductor, resonator and filter, etc., into a multilayered ceramic module) is an interesting solution in future communication satellites due to their outstanding performance and moderate cost. Currently, the LTCC products are being imported from vendors like DuPont, Ferro etc., and hence country’s revenue is getting drained owing to the exorbitant price of these products.

Indian Scientists have indigenously developed toxic-free and superior multilayer technology that packages together electronic components like resistors, capacitors to produce multilayer circuits. These technologies, known as Low-Temperature Cofired Ceramic (LTCC) and High-Temperature Cofired Ceramic HTCC substrates with applications as satellite communication components, are currently being imported in India. The indigenous development can plug the money drain through import substitution and support the country’s strategic sectors. Low orbit satellites satellite systems which are in demand today need a sustainable technology supporting reduced satellite volume and mass, besides reduced production time and affordable cost. Hybrid microsystems based on LTCC technology (integration of passive components, such as a capacitor, resistor, inductor, resonator and filter, etc., into a multilayered ceramic module) is an interesting solution in future communication satellites due to their outstanding performance and moderate cost. Currently, the LTCC products are being imported from vendors like DuPont, Ferro etc., and hence country’s revenue is getting drained owing to the exorbitant price of these products.

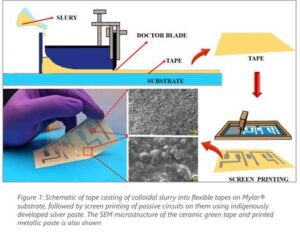

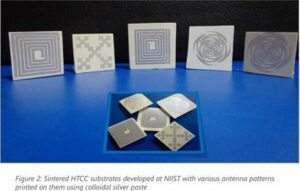

Hence, Dr K.P. Surendran, Principal Scientist, Materials Science &Technology Division, CSIR-National Institute for Interdisciplinary Science and Technology NIIST, under the purview of Advanced Manufacturing Techniques scheme of Department of Science & Technology (DST), Govt. of India, developed a series of LTCC tapes and HTCC substrates which are on par with international standards. They have dielectric properties or the ability of storing electric energy in an electric field that are comparable to the commercial tapes, whereas thermal conductivity is better than them. A patent has already been filed on tape casting of HTCC substrate based on zircon. An aqueous tape casting technique has been developed, which is relatively health hazard free since it does not employ volatile organic components like xylene and methyl ethyl ketone. The technology developed is a glass-free LTCC tape casting composition, which can address the brutality issues of tapes. These tapes find application in various satellite communication components at the Space Application Centre, Ahmedabad (ISRO), which require thousands of microwave substrates every year as also in Deference Research laboratories and BHEL

Hence, Dr K.P. Surendran, Principal Scientist, Materials Science &Technology Division, CSIR-National Institute for Interdisciplinary Science and Technology NIIST, under the purview of Advanced Manufacturing Techniques scheme of Department of Science & Technology (DST), Govt. of India, developed a series of LTCC tapes and HTCC substrates which are on par with international standards. They have dielectric properties or the ability of storing electric energy in an electric field that are comparable to the commercial tapes, whereas thermal conductivity is better than them. A patent has already been filed on tape casting of HTCC substrate based on zircon. An aqueous tape casting technique has been developed, which is relatively health hazard free since it does not employ volatile organic components like xylene and methyl ethyl ketone. The technology developed is a glass-free LTCC tape casting composition, which can address the brutality issues of tapes. These tapes find application in various satellite communication components at the Space Application Centre, Ahmedabad (ISRO), which require thousands of microwave substrates every year as also in Deference Research laboratories and BHEL

The technology is in the 5th stage of the Technology Readiness level, and Dr K.P. Surendran has signed an MoU with Ants Ceramics, Vasai, Maharashtra on LTCC tapes. These LTCC tapes and conductive pastes can be supplied to Space Application Centre (SAC), Ahmedabad, to be tested as a cost-effective replacement to the commercial LTCC tapes which they are currently importing. If the testing is successful, NIIST tapes can be employed in ISRO’s several microwave components like S- and C- band receivers for their satellite transponders. The knowledge generated in the AMT project has given NIIST confidence for developing an all gold system as a substitute for the imported commercial LTCC tape system currently being used in Space Application Centre ISRO for satellite applications. A project in this direction has been proposed under the ISRO Respond programme. Commercial exploration and mass production of this product is also being planned after testing the gold paste based LTCC tapes at SAC.